ແກ່ນ hexagon ກັບຄວາມສູງ 1.5D

ສົ່ງສອບຖາມ

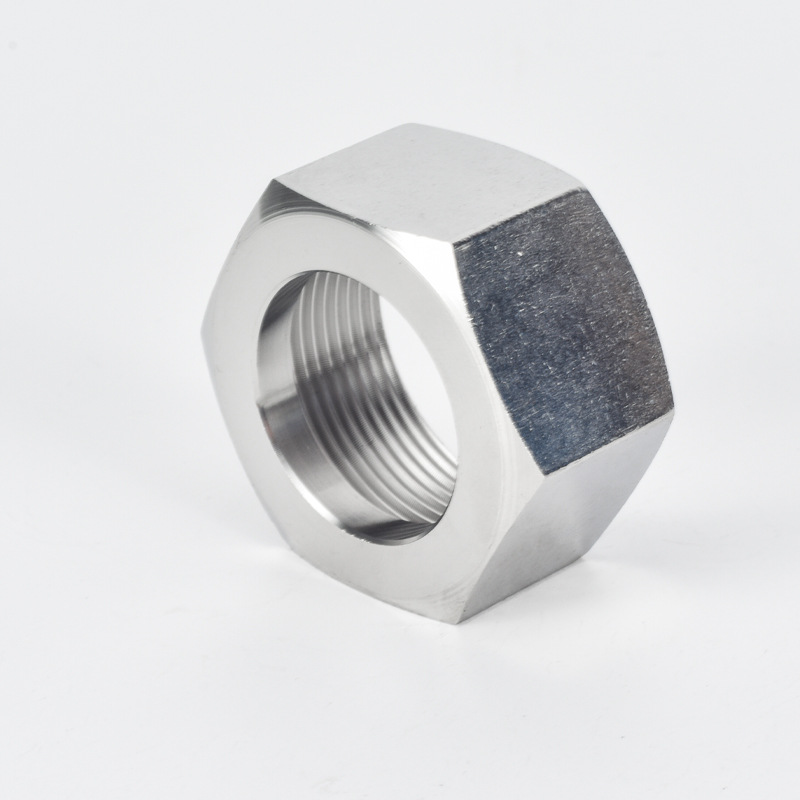

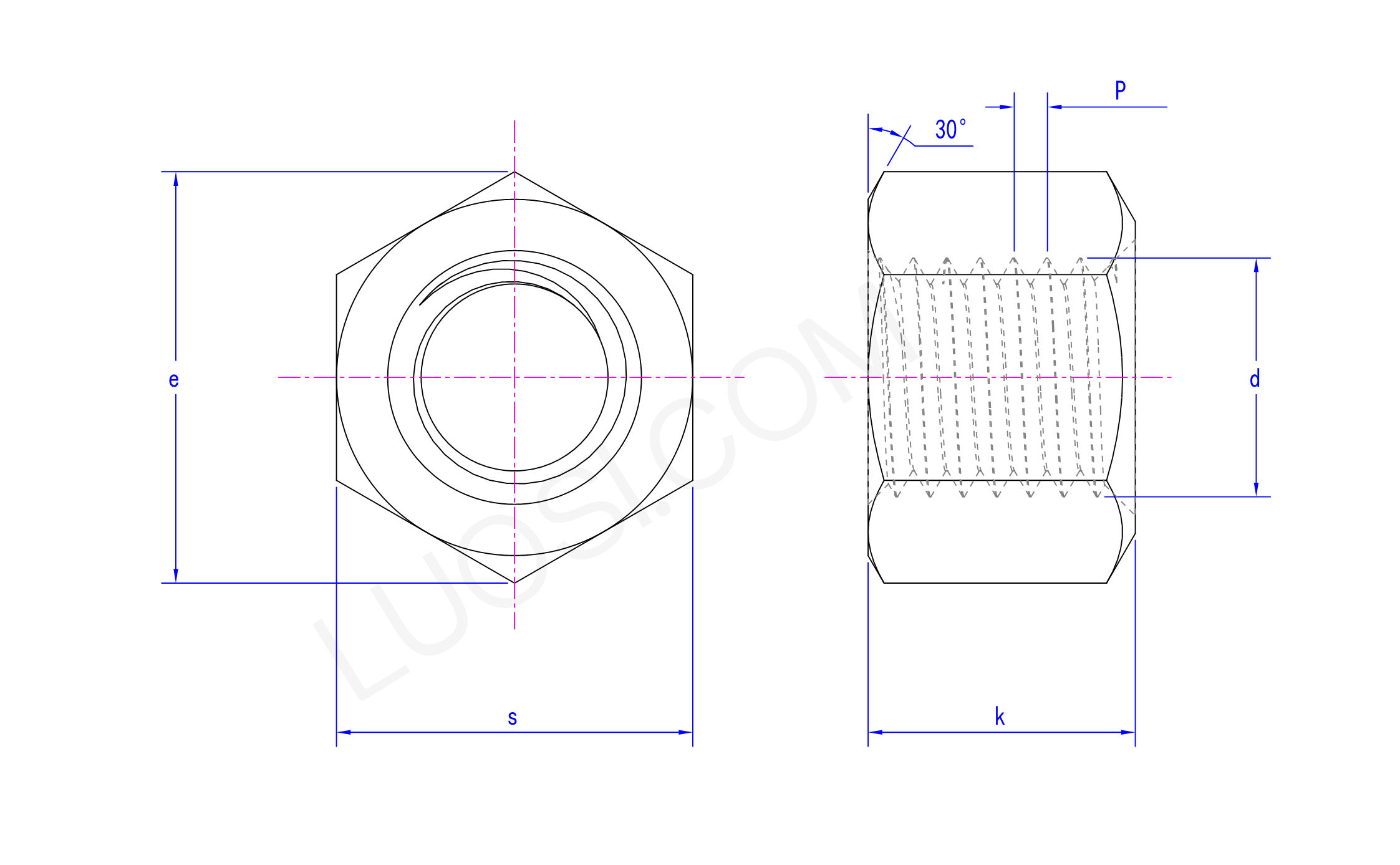

The height of the hexagon nuts with height 1.5d is equal to 1.5 times the diameter of the bolt (for example, the height of an M10 nut = 15mm). The hexadecimal edge is very sharp for the tool grip, and the thread is precisely cut according to ISO standards.

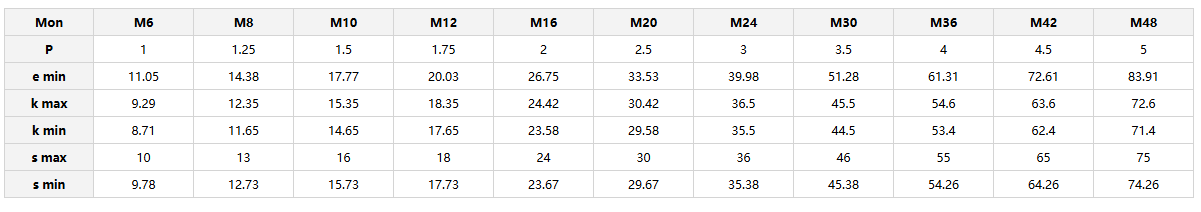

Product details and parameters

In the factory, hexagon nuts with height 1.5d vibrate more continuously than shorter nuts. Maintenance personnel use them on motor mounts, presses or robot arms. The additional threads can be tightened repeatedly without deforming. Expert tip: Mark with the paint color code to avoid mixing with the regular nuts in the toolbox.

Hexagon nuts with height 1.5d can provide you with additional thread interaction without the need to switch bolt sizes. It can reduce the wear of vibration Settings such as mechanical mounting seats or conveyor belts. Mechanics use them on heavy equipment. Over time, the regular nuts may become loose. You just need to check the clearance space first. Extra height may cause conflicts in tight positions.

To prevent the trailer hooks and flatbed straps from shaking on the highway, they will choose Hexagon nuts with height 1.5d to keep the goods safe. Truck drivers pair them with lock washers to increase safety. If the thread of the nut is completely covered, that would be great.

Our market distribution

|

Market |

Revenue(Previous Year) |

Total Revenue (%) |

|

North America |

Confidential |

20 |

|

South America |

Confidential |

10 |

|

Eastern Europe |

Confidential |

20 |

|

Southeast Asia |

Confidential |

2 |

|

Oceania |

Confidential |

5 |

|

Mid East |

Confidential |

5 |

|

Eastern Asia |

Confidential |

15 |

|

Western Europe |

Confidential |

20 |

|

South Asia |

Confidential |

5 |

Installation Tips

Inspect the surface and interior of the hexagon nuts with height 1.5d to ensure that the nuts are rusty or the threads are worn. If the edge is circular or the thread is deformed, a new one needs to be replaced. When used outdoors, galvanized or stainless steel should be used.